WAREHOUSE AUTOMATION

Moffett Automated Storage

With 7 decades of engineering excellence, the Moffett name is synonymous with innovation, from designing solutions for palletized goods to facilitating international storage.

Slide title

Write your caption hereButton

About Moffett Automated Storage

Privately held and established by industry experts in 2017, providing businesses across a range of sectors with material handling solutions that are data-driven, fully automated and bespoke to our clients’ requirements.

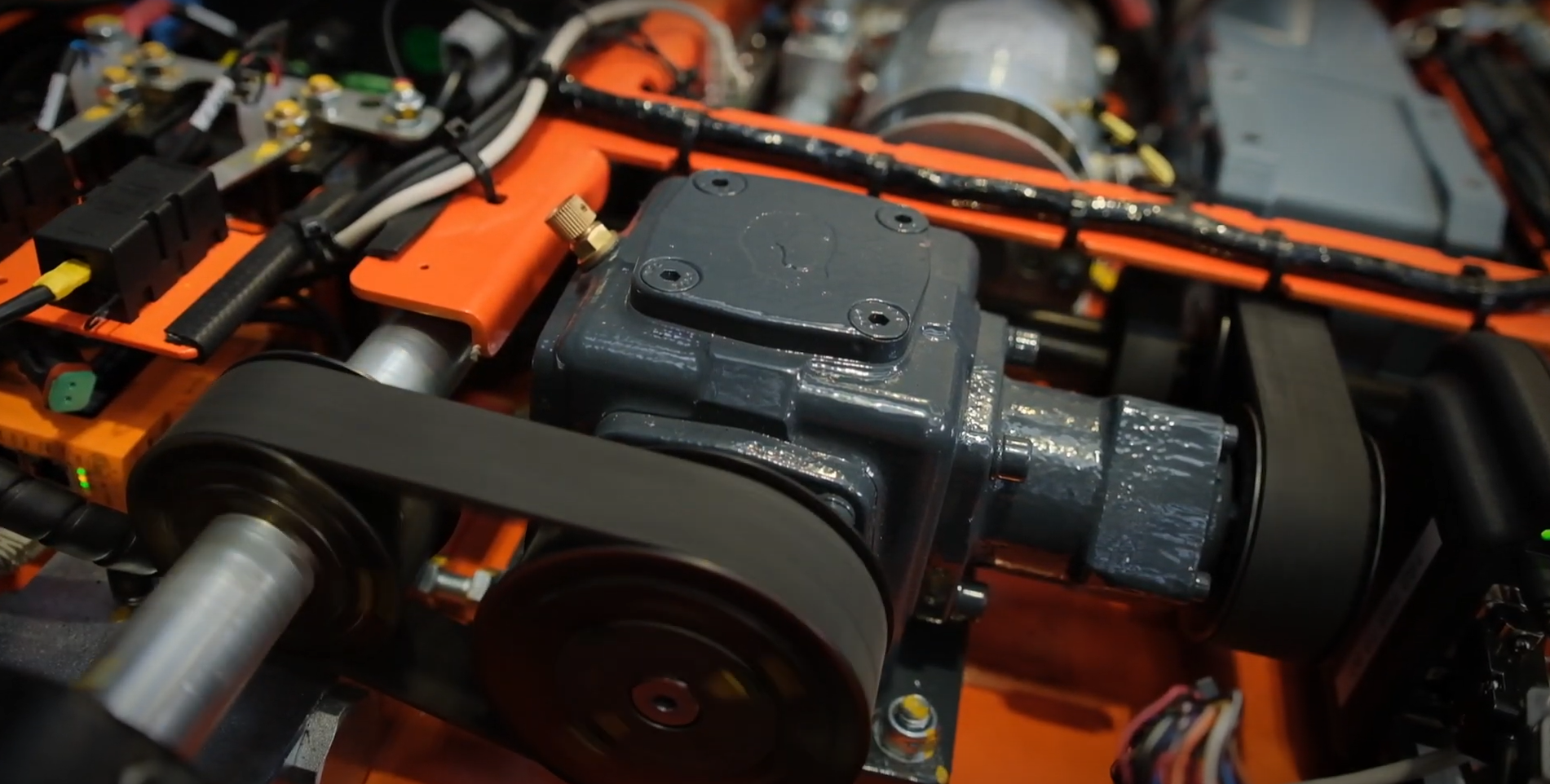

Moffett Storage offers an approach that is flexible, dynamic and with built-in redundancy. Our pioneering of the multi-directional Moffett AS/R Taxi System is testament to our commitment to innovation. The Moffett AS/R Taxi System provides a total re-definition of the concept of a traditional shuttle in the form of an auto storage retrieval system.

Pallet Inspection

The Moffett Automated System comes with a pallet/load inspection that determines if the load is suitable to enter the system and within the tolerances to ensure smooth operation. The cameras and laser sensors will scan the load, reading any barcodes to add the to the WMS. It will also check the condition of the pallet and weight. If all the tolerances are met, the light goes green and the pallet will move along the infeed and the WES will send a taxi to collect and position the load somewhere within the system. If for any reason the pallet, wrapping, bar codes, dimensions or weights are not within the required tolerance, then the system will send the pallet to the rejection lane and will be sent back to the packaging process.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Infeed System

The innovative Moffett AS/RS Four-Directional Taxi System maximizes available floor space, increases storage density, and boosts productivity rates, providing benefits such as higher picking accuracy, faster order fulfillment, reduced labor costs, improved safety, better inventory control, and greater adaptability to fluctuating demands compared to conventional storage methods.

What makes us different

Automated Storage and Retrieval Systems (AS/RS) for oversized loads are designed to handle larger, heavier items not suitable for standard AS/RS systems. Using specialized equipment like gantries or overhead cranes, they store items in dedicated storage bays. Controlled by software for safe, efficient storage and retrieval, these systems offer increased storage density, improved inventory control, and enhanced operational efficiency for industries needing storage of large, heavy items.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Outbound Process

Automated Storage and Retrieval Systems (AS/RS) for oversized loads are designed to handle larger, heavier items not suitable for standard AS/RS systems. Using specialized equipment like gantries or overhead cranes, they store items in dedicated storage bays. Controlled by software for safe, efficient storage and retrieval, these systems offer increased storage density, improved inventory control, and enhanced operational efficiency for industries needing storage of large, heavy items.

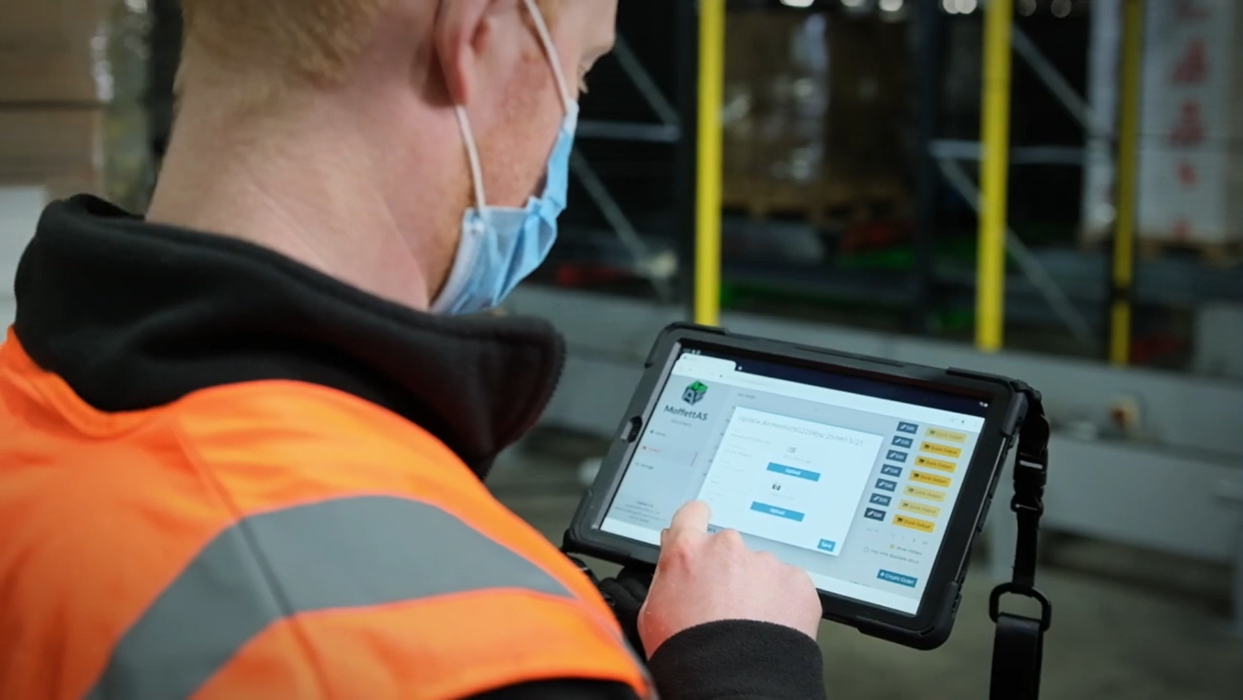

Technical Support

Automated Storage and Retrieval Systems (AS/RS) for oversized loads are designed to handle larger, heavier items not suitable for standard AS/RS systems. Using specialized equipment like gantries or overhead cranes, they store items in dedicated storage bays. Controlled by software for safe, efficient storage and retrieval, these systems offer increased storage density, improved inventory control, and enhanced operational efficiency for industries needing storage of large, heavy items.

Slide title

Write your caption hereButton

350K+

PALLET LOCATIONS INSTALLED

115

PROJECTS COMPLETED

100+

COUNTRIES SERVED

600%

EMPLOYEES

OUR TEAM ARE READY TO SHOW YOU THE BENEFITS OF A MOFFETT AUTOMATED SYSTEM

Want to share some of this information with your colleagues, click to download the PDF.

Check out the latest YouTube videos of the Moffett Automated Storage system.

LEARN MORE ABOUT

AUTOMATED STORAGE & RETRIEVAL SYSTEM (AS/RS)

Implementing automated storage and retrieval systems (AS/RS) into a business can significantly improve warehouse efficiency and productivity. Automated storage and retrieval systems use advanced technologies such as robotic shuttles, conveyors, and cranes to store and retrieve items from inventory, making it possible to automate material handling and reduce the need for manual labor.

Implementing AS/RS can be a complex process, requiring careful planning, design, and implementation. However, with the right tools and expertise, it can lead to significant improvements in your business's warehouse efficiency, accuracy, and overall performance.

SUCCESSFULLY INSTALLED PROJECTS

-

Artopex

View ProjectMANUFACTURING

-

Entrepôt 10/35

View ProjectFOOD & BEVERAGE

-

Jenna Food Products

View ProjectFOOD & BEVERAGE

Let’s talk about your project

Work with the best warehouse pallet racking systems consulting company & industrial storage installation services in Canada. Meet our supply chain consultants in Toronto, Montreal, and Mississauga.

Schedule a call

Select a time that works best for you and an expert will be available.

About

Access

Resources

Policies