SAFETY SOLUTIONS

Industrial Pallet Racking Inspections

Prioritize safety and protect your warehouse operations and employees. Invest in pallet racking inspections, paired with racking protection for a secure and efficient workplace.

Introduction to Industrial Pallet Racking Inspections

In the fast-paced industrial warehouse sector, the integrity of pallet racking systems is vital for the smooth flow of operations. Pallet racking inspections involve thorough assessments of these storage structures to ensure their safety, functionality, and compliance with regulations. These inspections encompass visual inspections, load capacity assessments, and identification of potential hazards. By implementing regular inspections, warehouse managers can proactively detect and address issues such as damaged components, overloading, and improper installations. This not only mitigates the risk of accidents and injuries but also safeguards the products stored on the racks, enhances compliance, and optimizes warehouse efficiency.

Enhanced Safety

Safety is paramount in the industrial warehouse sector, and pallet racking inspections play a crucial role in ensuring a safe working environment. These inspections help identify potential safety hazards such as damaged components, inadequate bracing, or overloading. By promptly addressing these issues, warehouse managers can mitigate the risk of accidents, including collapses or falls, that can cause harm to workers and damage valuable inventory. Regular inspections also demonstrate a commitment to safety, boost employee morale, and create a culture of vigilance in maintaining a secure workplace for all.

Compliance with Regulations

Complying with local, regional, and national safety regulations is paramount in the industrial warehouse sector, and pallet racking inspections play a vital role in meeting these requirements. Regular inspections ensure that the pallet racking system adheres to relevant codes and standards, minimizing the risk of non-compliance and potential legal ramifications. By conducting inspections, warehouse operators demonstrate their commitment to maintaining a safe working environment and meeting the necessary regulatory obligations. This proactive approach helps prevent costly fines, penalties, and legal issues, ensuring a smooth and compliant operation.

Damage Prevention

Pallet racking inspections are essential for identifying and addressing potential damage to the racking system. By regularly inspecting the components, warehouse operators can promptly detect signs of wear, corrosion, or structural weakness. Timely repairs or replacements of damaged elements prevent further deterioration and potential rack failures, ensuring the safety of personnel and protecting valuable inventory. By mitigating the risk of collapses or failures, pallet racking inspections help safeguard against costly product losses, reduce downtime for repairs, and maintain the overall integrity and reliability of the pallet racking system.

Longevity of Pallet Racking System

Regular pallet racking inspections play a crucial role in ensuring the longevity of the racking system. By conducting inspections, warehouse operators can identify signs of wear and tear, corrosion, or other factors that may compromise the structural integrity of the racks. Prompt maintenance and repairs, based on inspection findings, can prevent further deterioration and extend the lifespan of the pallet racking system. By proactively addressing issues, warehouse managers can avoid costly replacements, minimize downtime for repairs, and ensure the sustained functionality and durability of the racking infrastructure, ultimately resulting in long-term cost savings.

Professional Pallet Racking Inspection Services

Engaging professional inspection services offers numerous advantages. These experts possess specialized knowledge and expertise in assessing the structural integrity, safety, and compliance of pallet racking systems. They are well-versed in industry standards and best practices, ensuring comprehensive and accurate inspections. Using their experience, warehouse staff can gain valuable insights, actionable recommendations, and customized solutions. Professional inspection services provide peace of mind that the racking systems are thoroughly evaluated by qualified professionals, thereby maximizing safety, minimizing risks, and optimizing overall warehouse efficiency.

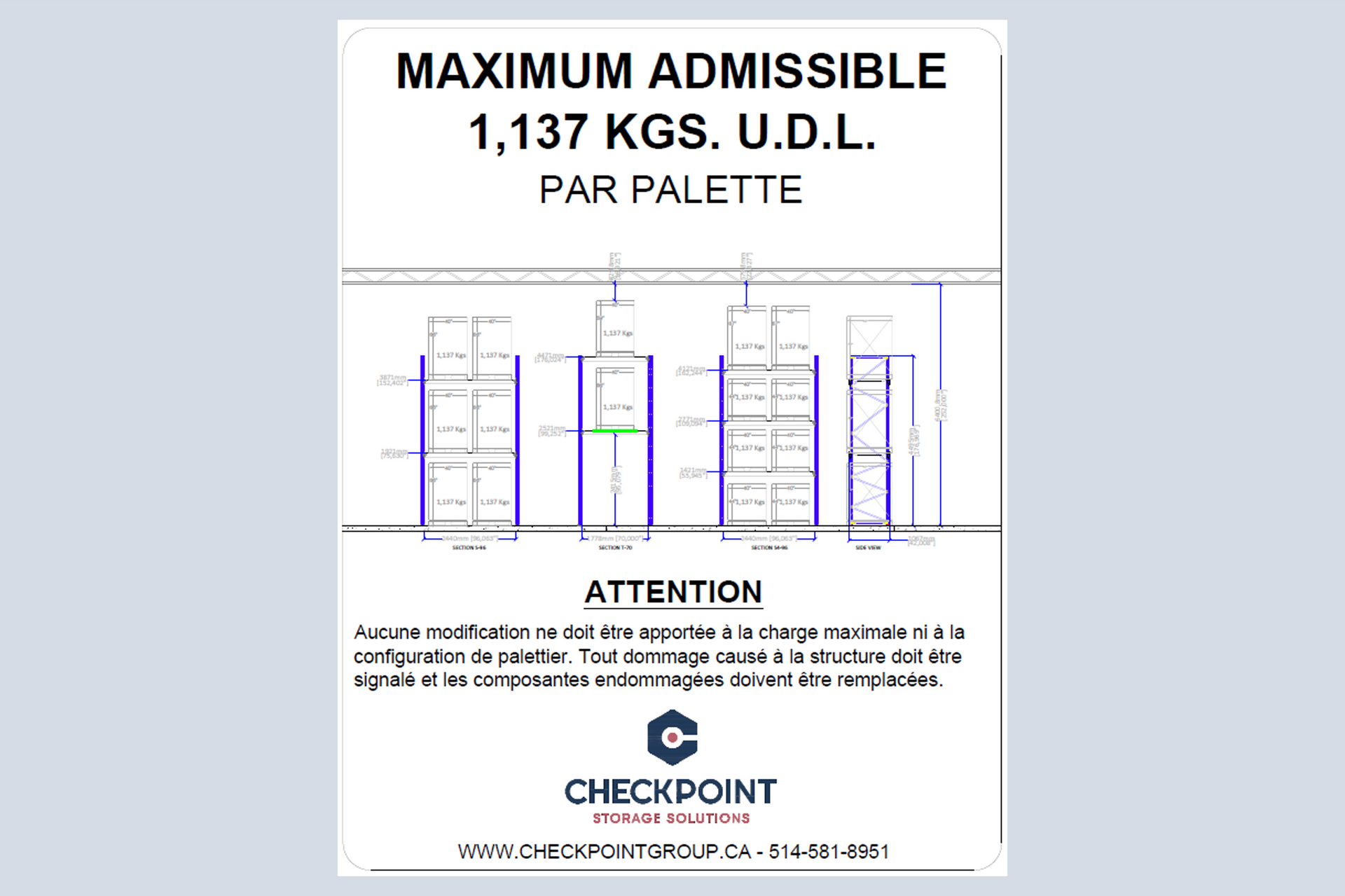

The importance of Capacity Signs

Load capacities displayed on pallet racking are crucial for safe and efficient warehouse operations. These weight limits indicate the maximum load the racking can safely support, preventing overloading and potential accidents. Adhering to these capacities maintains rack integrity, safeguards personnel, and protects inventory. It also optimizes storage space utilization, aligning with design specifications. Understanding and following load capacities displayed on racking ensures a safe work environment, preserves product integrity, and enhances overall operational efficiency.

90%

RACKING DAMAGE

CAUSED BY FORKLIFTS

25%

FATALITIES STUCK BETWEEN

FORKLFIT AND RACKING

2x

MORE WAREHOUSE STAFF

SINCE 2013

#1

DAMAGE TO RACK POST'S IS REACH TRUCK OUTRIGGERS

SPEAK WITH OUR INDUSTRIAL PALLET RACKING INSPECTION CONSULTANTS TODAY

Serving Montreal, Toronto, Mississauga, and all across Canada.

LEARN MORE ABOUT

SAEFTY IN THE WORK PLACE

For a FREE Workplace Safety Evaluation

Enhance workplace safety with a comprehensive evaluation that prioritizes racking, forklift trucks, and warehouse employees. Assess the integrity of racking systems to prevent collapses, prioritize regular maintenance for forklift trucks to mitigate accidents, and ensure employees receive proper training and adhere to safety protocols. By identifying potential hazards, implementing preventive measures, and fostering a culture of safety, you can create a secure work environment, reduce injuries, protect valuable assets, and optimize overall productivity in your warehouse operations. Invest in safety evaluations today to safeguard your workforce and improve operational efficiency.