INDUSTRIAL WAREHOUSE AUTOMATION

Automating your warehouse can bring significant advantages such as increased efficiency, improved accuracy, and optimal productivity, all while reducing labor costs and human error.

Why automate your warehouse?

Automating your warehouse can improve efficiency, accuracy, and safety while reducing labor costs. It enables faster order fulfillment and inventory management, eliminates manual errors, maximizes space utilization and builds for the future.

Transport and sort products or packages in a production or distribution operation.

Perform tasks that ensure maximum productivity in demanding applications.

Pick and fulfill orders using robotic arms, conveyors, and sortation systems.

Store and retrieve products in a warehouse or distribution center, optimizing space utilization with increasing accuracy and efficiency.

Use robots and conveyors to efficiently package and palletize products, increasing accuracy and speed in the packaging and shipping processes.

The use of various software, hardware, and automation solutions aimed at improving the efficiency, accuracy, and safety of material handling and storage processes.

SPEAK WITH A CONSULTANT IN WAREHOUSE AUTOMATION TODAY

Serving Montreal, Toronto, Mississauga, and all across Canada.

Rigid package sortation is for standard shape and size, whereas flexible package sortation is for items that are more diverse in shape and size.

Mixed package sortation increases the efficiency & accuracy of package handling & delivery, also reducing labor costs & minimizing human error.

Pallet conveyor systems are a type of equipment that are used to move pallets through a warehouse or distribution center to a specific point.

The use of automated equipment and technology to move, store, and retrieve pallets within a warehouse or distribution center.

The movement, storage, and handling of individual items. This is typically used in manufacturing, assembly, and distribution operations.

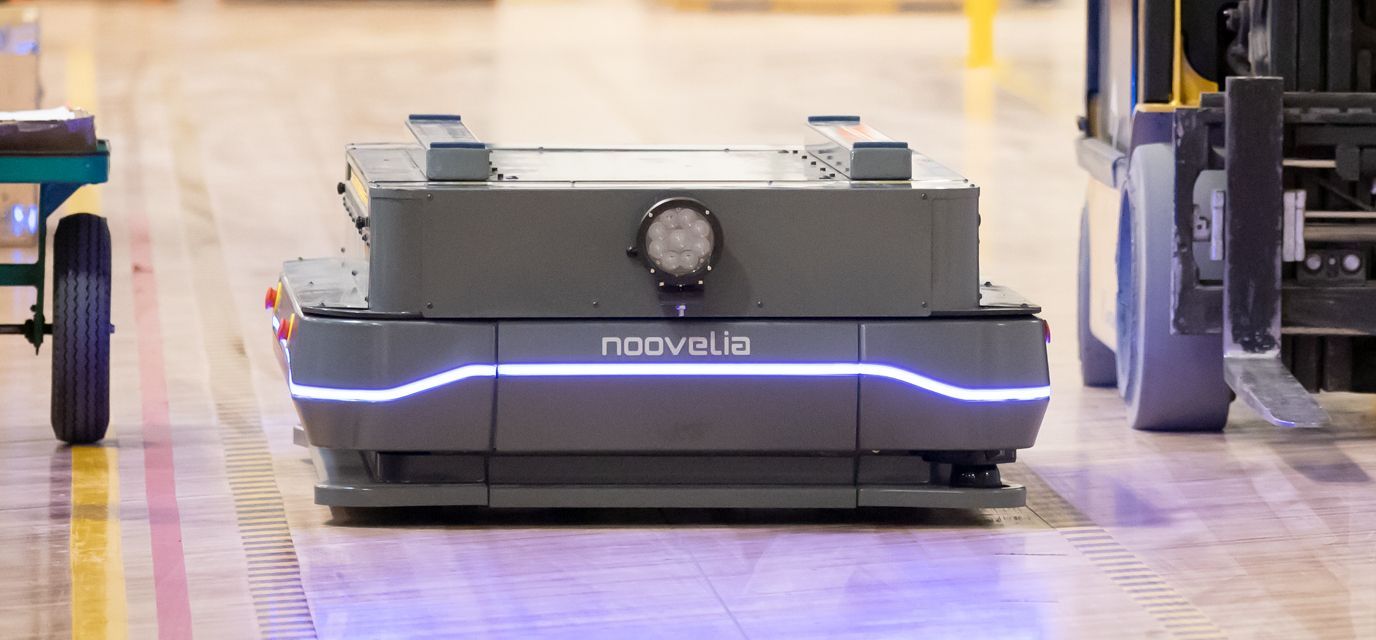

Automated vehicles and robots can be used to safely and efficiently move over-sized loads, such as large machinery or heavy goods.

Mini Load ASRS are a type of automated material handling equipment that is used to store and retrieve small parts, items or containers.

Using a series of trays or shelves that are stored in a vertical tower, a VLM is designed to access and retrieve the items efficiently.

Lights indicate the location & quantity of items to be picked. This system is used to improve the accuracy & efficiency of order picking.

This ASRS system is used to store and retrieve oversized loads in a high-density system. Using high-capacity racking, a crane and WCS control system.

A type of automated storage and retrieval system that is used to store and retrieve pallets in a high-density storage rack using a shuttle.

This ASRS system is used to store and retrieve pallets in a high-density system. It consists of a storage rack, a stacker crane, and WCS control system.

An automated packaging system is a type of equipment and technology that is used to package, seal, and label products in a warehouse or distribution center.

A palletizing system is a type of automated equipment that is used to arrange and stack products, such as boxes, bags or crates, onto a pallet.

A type of automated equipment to secure, stabilize, and immobilize loads during transportation within a warehouse or distribution center.

A Warehouse Management System (WMS) is a software application that helps to control and manage the operations of a warehouse or distribution center.

A Warehouse Execution System (WES) is a software application to manage and automate the execution of warehouse operations, picking, packing, and shipping.

A Warehouse Control System (WCS) is a software application that helps to manage and control the automated systems and equipment used in a warehouse.

Join a growing number of businesses relying on Checkpoint Group

LEARN MORE ABOUT

INDUSTRIAL WAREHOUSE AUTOMATION TECHNOLOGY

Implementing automation can be a game-changer for businesses, allowing them to streamline operations, increase efficiency, and improve overall productivity. By automating routine and repetitive tasks, businesses can reduce the risk of errors, save time and money, and free up employees to focus on more strategic work. However, successful implementation of automation requires careful planning, assessment of the business's needs, and identification of the most appropriate automation tools and technologies.