WAREHOUSE AUTOMATION

Automated Storage & Retrieval Systems

AS/RS Consultant Services

Automated Storage & Retrieval Systems (AS/RS) are used to store and retrieve products in a warehouse or distribution center, optimizing space utilization with increasing accuracy and efficiency.

The benefits of an Automated Storage & Retrieval Systems (AS/RS)

An Automated Storage & Retrieval System (AS/RS) brings a range of significant benefits, revolutionizing the way businesses manage their storage and retrieval operations. One of the primary advantages of an AS/RS is its ability to optimize storage space. By utilizing vertical height and employing advanced technology, an Automated Storage & Retrieval Systems (AS/RS) can efficiently store and retrieve items optimizing space. This allows businesses to store more products within a smaller footprint, effectively utilizing their warehouse space.

Pallet Shuttle System

A Pallet Shuttle System is a high-density automated storage solution with a shuttle moving within a rack to handle pallets. Reducing aisle space compared to traditional systems, it stores more pallets in a smaller footprint. The shuttle, controlled for specific pallet retrieval and movement, improves inventory control and operational efficiency. This flexible, scalable, and cost-effective system addresses warehouse storage and retrieval needs.

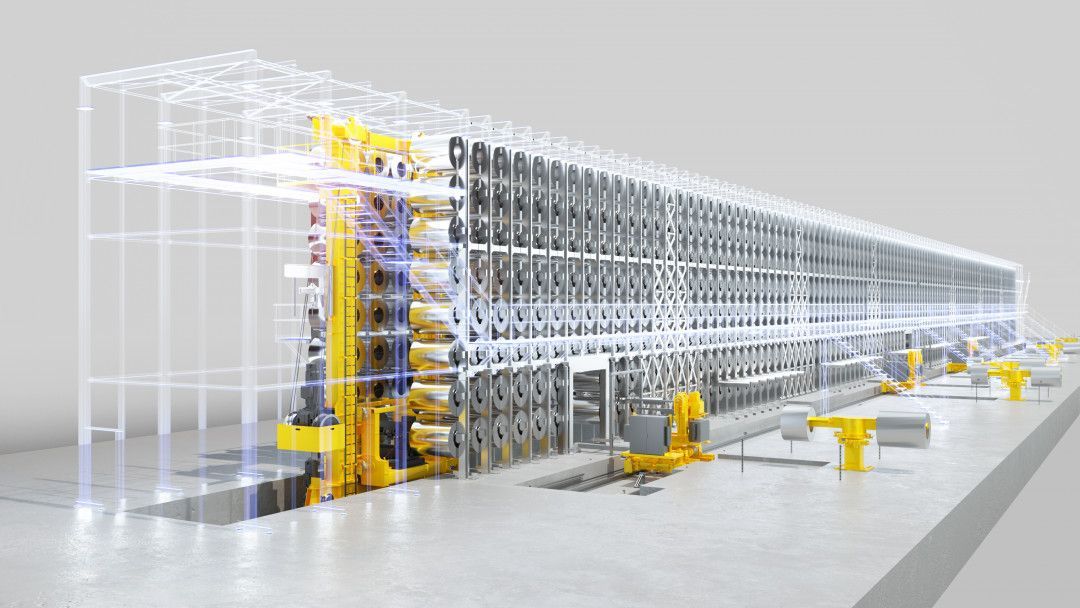

Stacker Crane Systems

A Stacker Crane System is an automated storage and retrieval system with a crane moving along rails to access storage bays horizontally and handle items vertically. Used for high-density storage of various items, it is controlled by software for specific item retrieval. The system can also move items within the warehouse, offering increased storage density, improved inventory control, and enhanced operational efficiency compared to traditional systems.

Multi-Directional - Automated Storage & Retrieval Systems (AS/RS)

The innovative Moffett Automated Storage & Retrieval Systems (AS/RS) Four-Directional Taxi System maximizes available floor space, increases storage density, and boosts productivity rates, providing benefits such as higher picking accuracy, faster order fulfillment, reduced labor costs, improved safety, better inventory control, and greater adaptability to fluctuating demands compared to conventional storage methods.

Oversized Loads

Automated Storage and Retrieval Systems (AS/RS) for oversized loads are designed to handle larger, heavier items not suitable for standard AS/RS systems. Using specialized equipment like gantries or overhead cranes, they store items in dedicated storage bays. Controlled by software for safe, efficient storage and retrieval, these systems offer increased storage density, improved inventory control, and enhanced operational efficiency for industries needing storage of large, heavy items.

Speak with our Automated Storage & Retrieval Systems (AS/RS) Consultants

Serving Montreal, Toronto, Mississauga, and all across Canada.

LEARN MORE ABOUT

AUTOMATED STORAGE & RETRIEVAL SYSTEM (AS/RS)

Implementing automated storage and retrieval systems (AS/RS) into a business can significantly improve warehouse efficiency and productivity. Automated storage and retrieval systems use advanced technologies such as robotic shuttles, conveyors, and cranes to store and retrieve items from inventory, making it possible to automate material handling and reduce the need for manual labor.

Implementing Automated Storage & Retrieval Systems (AS/RS) can be a complex process, requiring careful planning, design, and implementation. However, with the right tools and expertise, it can lead to significant improvements in your business's warehouse efficiency, accuracy, and overall performance.